The cellular caissons

The New Genoa Breakwater's structure will be divided into modules: i.e. the cellular caissons (named as such due to the fact that inside them they are divided into cells, empty cavities that will be then filled with stone material).

These reinforced concrete giants are as tall as buildings. They are laid one next to the other upon the submerged base to give a shape to the breakwater. The first to be laid measures 21.7 metres in height, 25 in width and 40 in length, while the larger ones will even reach 33 metres in height, 30 in width and over 67 in length.

Building the caissons is one of the most complex parts of this work, and on average requires 20 days and engages approximately 50 people.

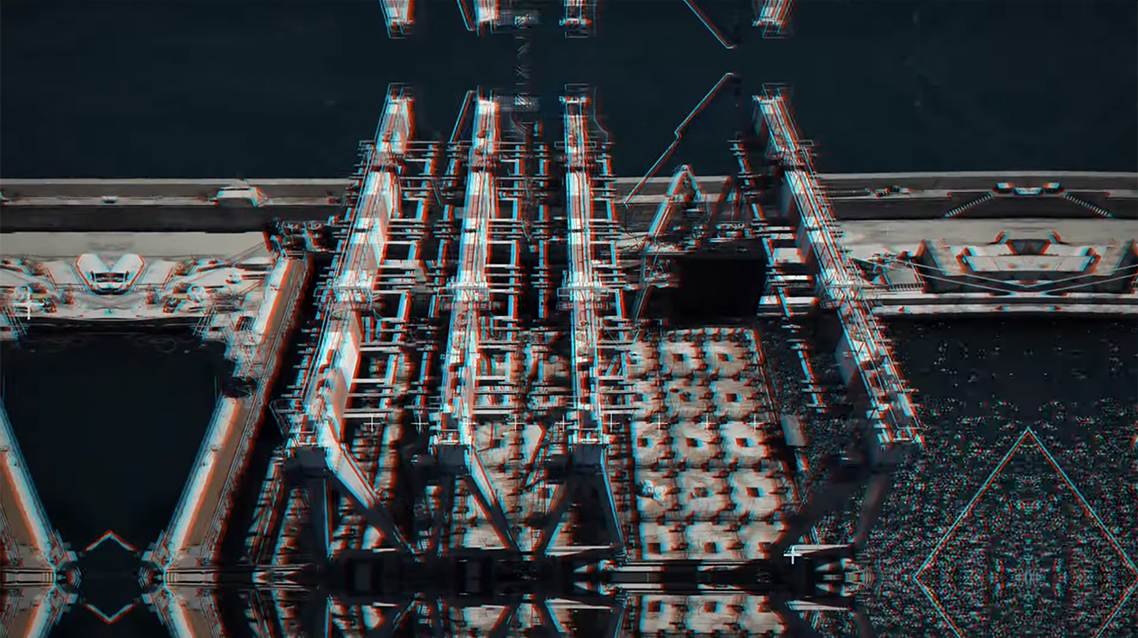

The caissons are made directly at sea: the metal formwork is placed on a floating platform. The formwork is the perfect splitting image in terms of structural dimensions of the caisson that is to be built. The distancing systems and the metal cage are positioned, and then the first jet of concrete is carried out. When the concrete has solidified, the formwork is raised a few metres and the process is then repeated until the desired height is reached.

Once the caisson has been built, it is moved to the pre-established location where it will be positioned by using tug boats. Then it is sunken, by filling the cells with sea water and once it has been laid on the base, the cells are then also filled with rock material.

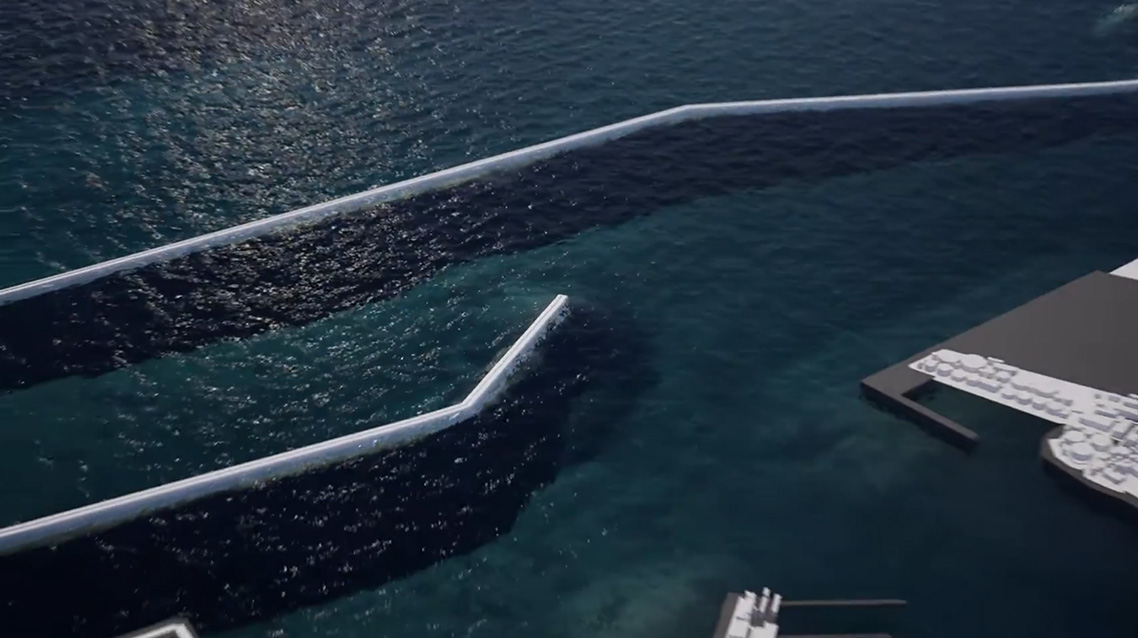

The caissons are then completed at sea: it is closed by a superstructure on which the seawall is placed, the most visible part of the breakwater, which has been designed to reduce the effects of the impact of the waves.

The caissons are made by applying sustainability principles when they are built: an innovative concrete mix is used to significantly increase its waterproof quality, while the inside is filled with recycled inert material, also with the material taken from the old breakwater's demolishing.

How they are built